Humidification & humidity control

in tobacco production

Tobacco leaves, cut tobacco and paper are all extremely hygroscopic which means that they give up their moisture to the surrounding environment if the air is too dry. Dry air causes tobacco's properties to degrade resulting in shrinkage, weight loss, brittleness, flaking, splitting and tearing.

This causes tobacco to literally fall out of cigarettes, cigarette papers to misfeed on machines and cigar leaves to crack.

Maintaining the right level of ambient relative humidity prevents all these problems by ensuring that tobacco, paper and leaves retain moisture at the correct levels, so maintaining their quality and ensuring that production can proceed at full efficiency.

Recommended tobacco manufacturing humidity levels:

Primary production - 60-68%RH

Tobacco stores - 60-70%RH

Ripping rooms - 65%RH

Benefits of Condair humidification in the tobacco industry include:

- Extensive expertise around the world with many tobacco manufacturers

- Increased production efficiencies, reduced wastage, higher processing speeds

- Comprehensive product range to precisely meet customers' requirements

- Ability to provide innovative custom solutions for unique processes

- Low energy systems to reduce operating costs and improve humidity control

- Low maintenance solutions to reduce on-going service requirements

- Comprehensive service of advice, design, supply, installation, commissioning, maintenance and spares supply

- BAT

- ITC

- Imperial Tobacco

- Rothmans International

- Gallagher + Co Ltd

- Swedish Match

- World Duty Free

- Altadis

- Hunters & Frankau

- West Indian Tobacco

- Rizla

Other industries where Condair delivers vital humidity control

Condair GS at BAT Southampton

Condair has supplied two gas-fired humidifiers capable of delivering up to 480kg of steam per hour to British American Tobac...

Read moreTextile manufacturing humidification

For improved yield & quality.

Read morePharmaceutical manufacturing humidification

Increases efficiency & yields.

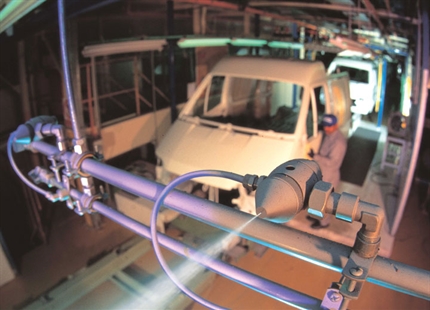

Read moreAutomotive manufacturing humidification

Increased efficiencies & accuracy.

Read more